If you’re serving meals in-cell or to pods, you know the importance of having a good meal delivery cart. We have a variety of Cook’s Brand Carts for meal delivery including Stainless Steel Tray Delivery Carts, Aluminum Tray Delivery Carts and the Rhino Cart family. It was during the development of the Rhino Carts that we that we really started to pay attention to casters. Want to know what sparked our interest in the different types of casters? The answer is easy – customer feedback. As it turns out, a bad caster makes for a bad cart. This feedback drove us to search for the best caster for the Rhino Tray Delivery Cart and ultimately lead us to the 8” Colson Performa Caster which are plate mounted. Here are some of the things we learned when we were looking for the right caster for correctional meal delivery carts.

Here Are The Basics About Casters

There are two different styles of mounts for casters:

1. Plate Mounted Casters feature a flat bracket with mounting holes so you can fasten the caster flush to another flat surface.

2. Stem Mounted Casters do not have a flat bracket, but rather a threaded pintle or a spring retention clip.

A plate mounted caster offers a larger surface area to apply the weight distribution compared to stem mount casters, so plate casters will have a higher load capacity. The big benefit to threaded stem casters is that they are easy to replace if they become broken or locked up by unthreading and repairing or replacing with a new caster. Additionally, threaded stem mounted casters have a cleaner appearance than a plate mounted casters.

There are also two different categories of caster, rigid and swivel:

1. Swivel casters have a raceway that allows the wheel in the caster to rotate 360 degrees while it is under load. The raceway is the cylindrical part of the swivel caster that contains the ball bearing track or tracks.

2. Rigid casters, also referred to as fixed casters, are only able to roll forward or backward.

Want to know an interesting bit of information that won’t help you at a dinner party, but may let you win at trivial pursuit? As the center hub of the wheel revolves around the center of the swivel section it is said to “cast” in that small circle – and that leads to the name: casters.

Caster Configurations

1. The most common configuration for casters is to have a pair of rigid casters and pair of swivel casters, with each pair positioned parallel to each other. This allows for easy turning and straight-line maneuvering.

2. On some carts, you will find all four casters to have the ability to swivel, making it more difficult to control than the traditional layout. The benefit to this layout is that it is easy to move light loads through tight locations. Ideally, two of the casters would feature caster locks making straight line travel less difficult.

3. Occasionally, you will find four rigid casters in a diamond pattern. This can be a cost effective solution as rigid casters are less expensive than swivel casters. Generally, when you come across a cart with this caster configuration, one pair of casters on the left and right sides is a bit taller than the par on the front and back sides so that the cart will be easier to pivot and turn with the load arranged over the central fixed casters.

Wheel Material & Size

The selection of the caster wheel material is determined by the surface you will be pushing the cart over, durability required and noise. The harder a caster is, the easier it is to push because harder materials have lower resistance or friction. This is particularly important as loads get heavier because it makes it much easier to get your cart moving with a hard caster. When you have casters that have a softer material, you can expect these to be quieter and they will reduce the vibration of the cart. If you are to be pushing a cart over a softer floor; like hardwood or tile, you may want to use a softer caster as a harder caster may mark or damage the floor.

You will find rubber, plastic and metal casters. Rubber is the softest of these materials but it can vary in softness. Plastic casters are typically harder than rubber casters, with variations in hardness for plastic too. Finally, metal casters are the hardest caster type.

Wheels are measured by the diameter and width. The diameter of a caster is the height of the wheel, where the overall height of a caster is the wheel and the mount. Wheels with greater diameter are easier to push; they have a lower resistance. Additionally, they can handle heavier loads and they are usually quieter. It is important to keep in mind that a cart with casters that have a larger diameter will have a higher center of gravity making it less stable which can be intensified when the cart has heavier loads stacked higher in the cart. For meal delivery, this can happen if you place loaded beverage servers on top of the cart. Additionally, with a meal delivery cart, if you do stack additional meal related items on top of the cart and the cart is raised up due to larger diameter wheels, that means that heavy items like filled beverage servers, need to be lifted up and take down from a higher height. While an inch or two may not seem like your adding a great deal of difference, it can become an issue for a person lifting a full five gallon beverage server weighing over 40 lbs. off the top of the cart.

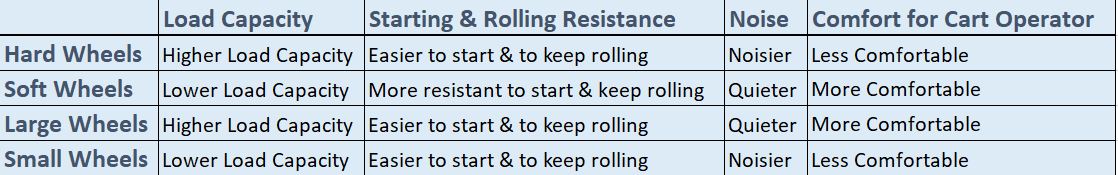

This matrix outlines how caster material and dimension will affect cart functionality:

Pneumatic and Semi-pneumatic Casters for Carts

Every year we receive requests for a pneumatic or semi-pneumatic caster for the Rhino Cart as well as alternative casters for our other meal delivery carts. First let’s cover the differences:

Pneumatic – these casters have a rubber wheel that is filled with pressurized air. It will provide a cushioned ride to, even over any uneven surfaces the cart needs to travel over and it will reduce noise.

Semi-pneumatic – these casters have a thick walled rubber tire that has a pocket of non-pressurized air inside. Like the Pneumatic casters, these provide cushioning for the cart but without the possibility of going flat.

While both of these casters will make a large, heavy cart easier to push, particularly over finished or unfinished concrete, ceramic or tile, they may not last as long as soft rubber or polyolefin casters. Of these two caster types, the Pneumatic caster is the most likely caster to become damaged particularly on a larger meal delivery cart that is heavy when fully loaded. There is also a third option, a Flat-Free caster wheel which has a solid rubber or polyurethane wheel that still provides some cushioning.

There’s a lot to know about casters, but don’t worry if you can’t keep it all straight in your head. Cook’s is always here to assist you in any of your equipment, supply and transport decisions.